Real-Time Inline Viscosity Control

SofraserWith an inline measurement you are able to increase the production capacity and quality of your products. Consider, for example, measuring the viscosity of paints, coatings, adhesives, sealants, melamine resins and plastics, colloidal silica, ink deposition on special films, or inline measuring the viscosity during the extrusion process of polymers.

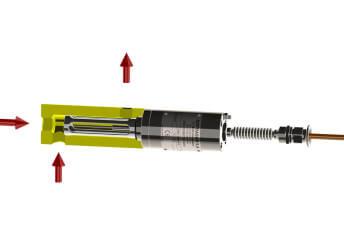

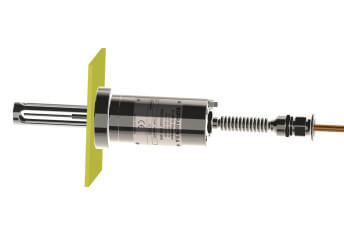

The MIVI sensor from Sofraser is a viscometer at resonance frequency. These viscometers ensure perfect texture, consistency and concentration. In addition, they have no moving parts; the instrument is therefore much less vulnerable (perfect for highly viscous liquids) and requires virtually no maintenance. You are able to safely produce more in a shorter time frame, without the risk of a shutdown and loss of raw materials.

The MIVI analyser from Sofraser is available in various versions with additional options. There are various mounting options, such as wall mounting (in a reactor or vessel), in-line (bypass) and in a measuring chamber (for small and flexible pipes). The sensor can also be installed on existing flanges of reactors and pipelines. Because the sensor is ATEX certified and performs under high pressure and at high temperatures, the measurement is ideal for heavy processes and demanding environments.

Key benefits

Would you like more information about Sofraser's inline viscometers? We are happy to help: info@inventech.nl or 0162-460404. Download the brochure here.

Receive information immediatelyPDF downloads

What would you like to measure?

Contact us for more information, we are happy to help.