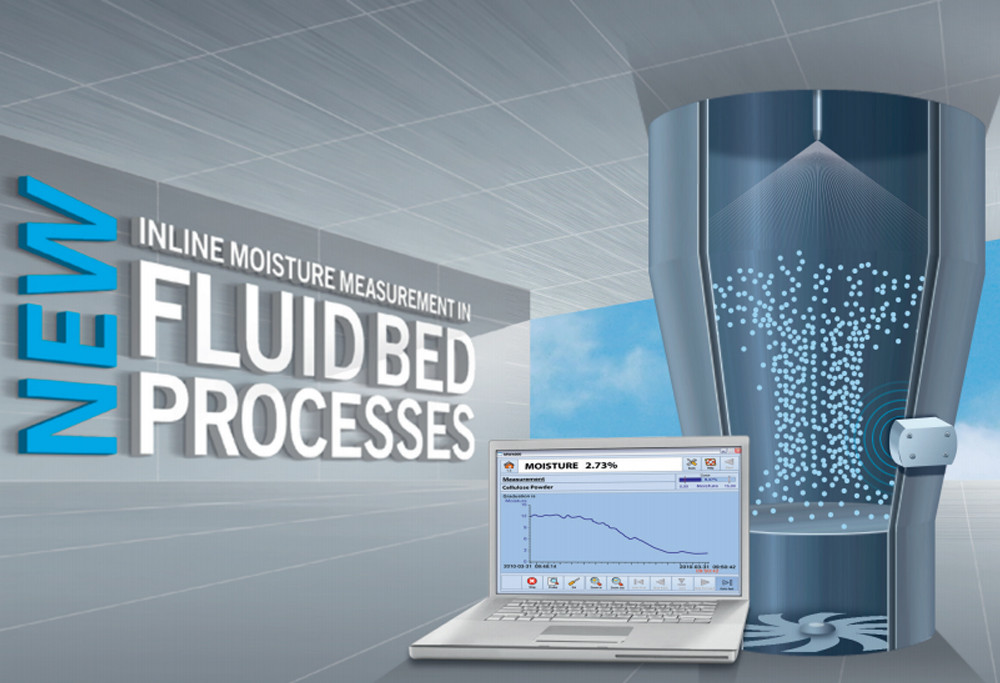

Inline moisture measurement fluid bed dryers

Inventech provides a moisture sensor for direct installation in fluid bed dryers and granulators. The sensor makes use of a low-energy microwave field which penetrates the granules and detects the water molecules inside as well as at the surface. Continuous measurement is performed during the drying process. The measuring values are independent of varying bulk density, varying particle size, distribution and color.