The Challenge of Textile Recycling

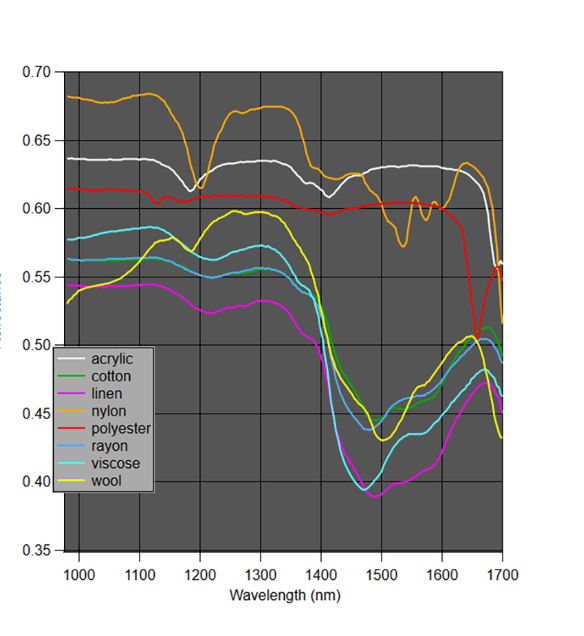

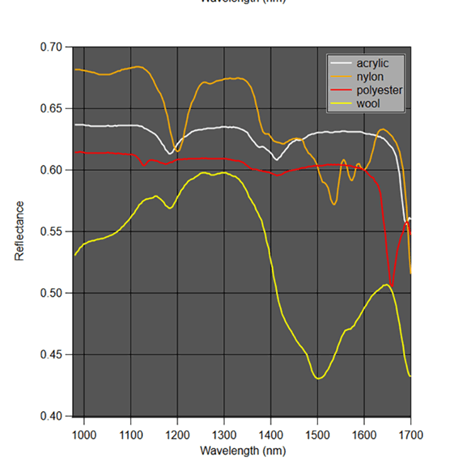

Textile recycling remains a significant global issue, with only 15% of post-consumer textile waste recycled while 85% ends up in landfills, according to the US EPA. Traditional sorting methods, like air classifiers, struggle with fabrics of similar density and texture, while chemical sorting methods, although precise, require destructive processes and are limited to specific materials like polyester.

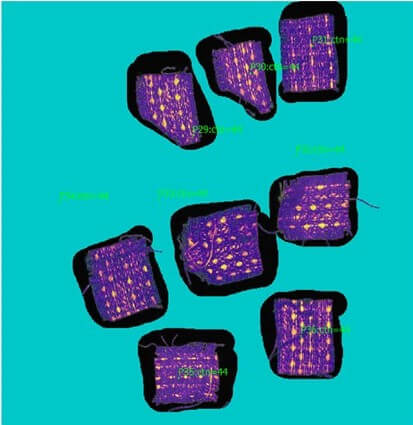

RGB and multispectral imaging, while providing some insights, fall short in distinguishing between fabrics with subtle differences. The ideal solution is a contactless sorting system that can classify diverse fabrics and blends at high speed. Headwall's hyperspectral imaging technology (HSI), combined with perClass Mira's machine learning software, addresses this challenge with unmatched precision and efficiency.