Inline viscosity measurement extrusionprocesses

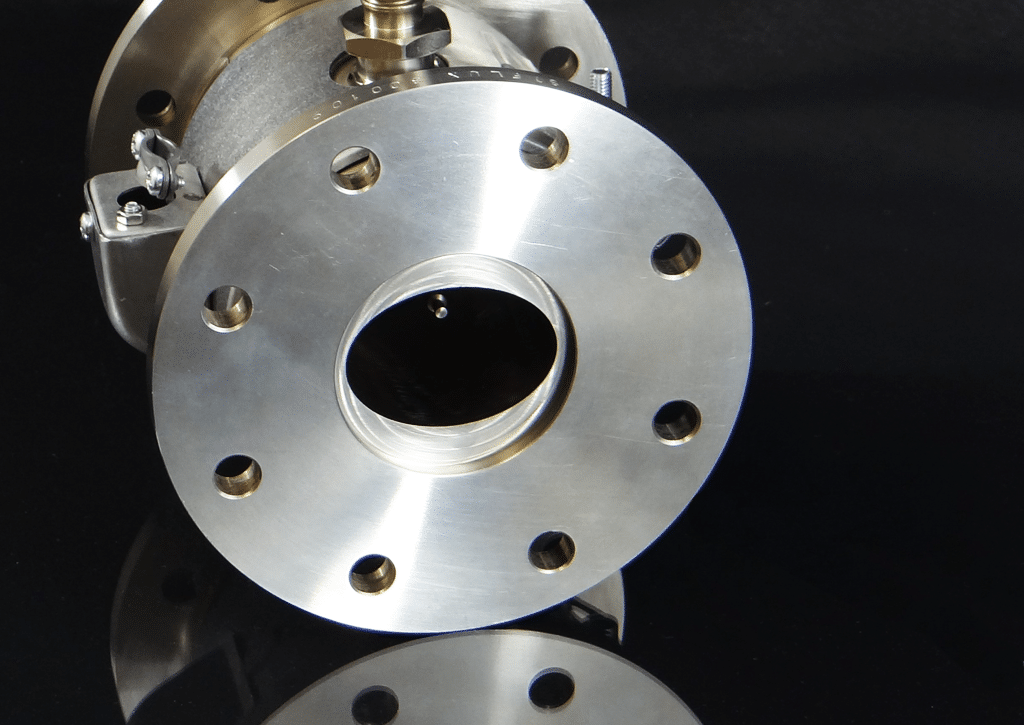

Soflux viscosity sensor is a new vibrating inline process viscometer with a dedicated shape allowing easy integration into any plastic, polymer or elastomer extruder. It is the ideal solution to monitor any extrusion process even the most demanding like speciality compounding, recycling, reactive extrusion...