Foreign Object Detection in Cheese

Recalls are costly and damaging to a brand’s reputation. Even a small packaging defect can force a recall of tens of thousands of packages of product. For example, a large chain of grocery stores issued a recall of several types of cheese for small shards of plastic that went undetected into plastic-wrapped blocks and grated pieces of cheese in plastic pouches.

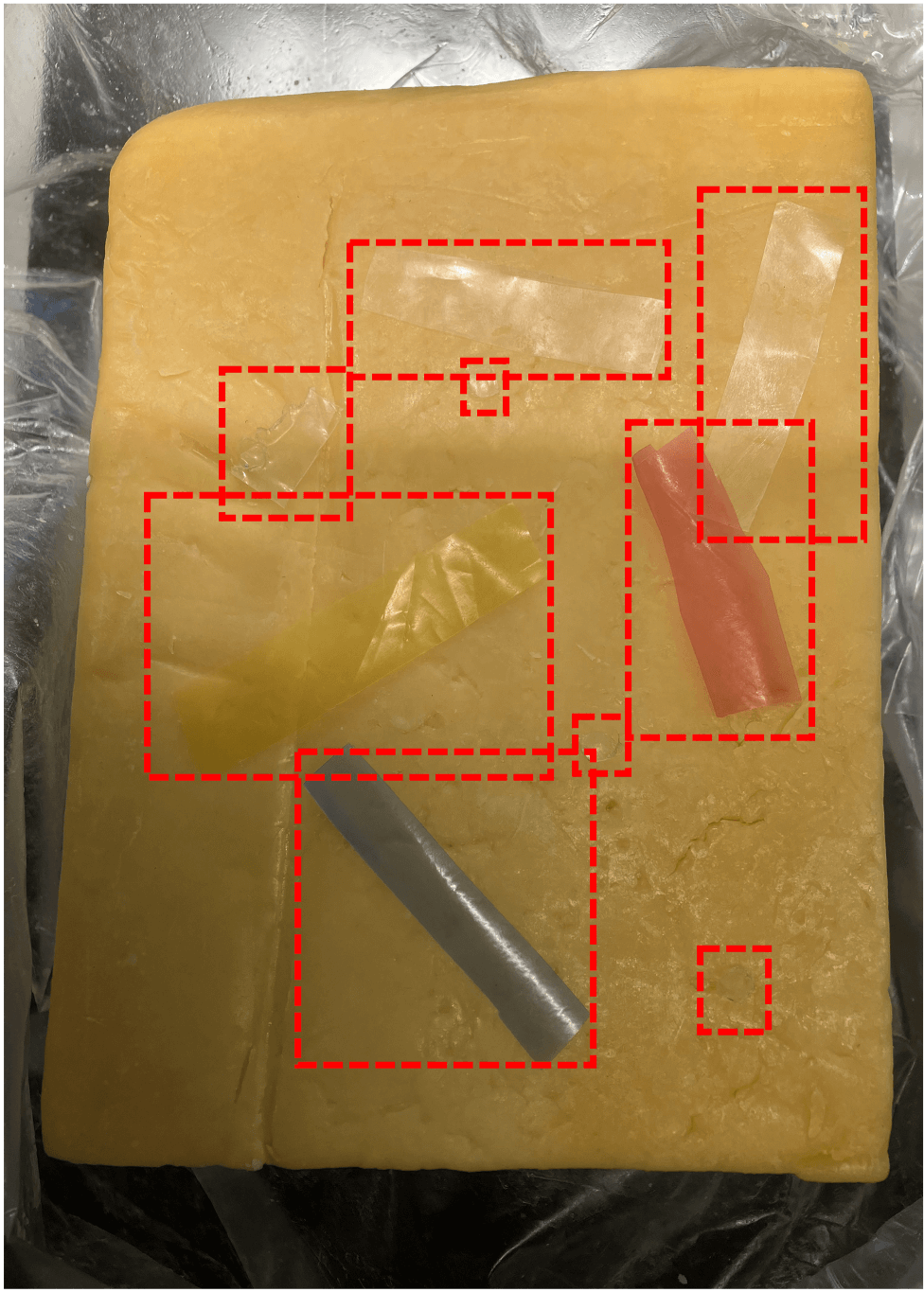

When large blocks of cheese are unwrapped, cut, and repackaged, processors must inspect the cheese for any remaining debris. Clear or even tinted plastic is notoriously difficulty to spot by eye or conventional inspection methods. If any pieces manage to get under the surface, it is likely that the contaminated cheese may be wrapped and sold to an unsuspecting consumer.

Once wrapped, conventional inspection methods have difficulty detecting debris underneath. However, hyperspectral imaging can provide a non-contact, real time detection method as the cheese—wrapped or unwrapped—travels along a conveyor to be sorted, packed, and shipped.

Headwall Group company perClass worked with GROBA, a maker of cheese-processing equipment, to determine how well hyperspectral imaging works for detecting contamination from plastics.

.png](https://www.inventech.nl/cache/4713a334f1039a4979540071aa22d5ef/updatedconfusionmatrix_1-5-24[1](1).png)